Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

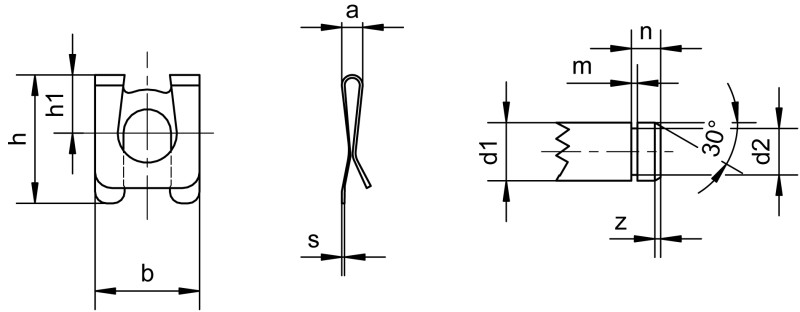

SL-retainers made of spring band steel are a reliable solution to prevent axial displacement on shafts, axles, and bolts with groove or a slot. They offer increased security compared to other retainers through a clip that encloses the end of the bolt, providing additional protection against axial displacement. SL-retainers impress with their ease of use: They can be quickly and easily installed both with and without special assembly tools. Another advantage is their reusability, allowing flexible use and long-term cost savings. The play-compensating property of SL-retainers offers the advantage that they can compensate for tolerances and unevenness during assembly to ensure a secure and tight connection. Even with imperfectly matched components, unwanted movements and loose fits under load are effectively prevented, increasing the reliability and stability of the connection and minimizing the risk of wear or damage. Made from high-quality spring band steel, SL-retainers are characterized by excellent spring force and durability, making them ideal for demanding applications. They are available in various sizes for shaft diameters from 4 mm to 16 mm, making them suitable for a wide range of technical requirements. Thanks to their robust construction and diverse application possibilities, SL-retainers are used in machine building, vehicle construction, and conveyor technology, among others. They offer reliable and permanent fixation that withstands the high loads in these areas.

2. Product details

Size: 4 mbo 08 - 16 mbo 08

Material group: Steel

Surface: electr. galvanised white, phosphatised oiled

3. Application Areas & Compatibility

Mechanical engineering: SL-retainers secure mechanical connections in industrial equipment and machinery, providing protection against axial pull and ensuring durable, secure connections under demanding conditions.

Automotive engineering: The retainers are used in the production of vehicle components such as the engine, chassis, and other critical parts to ensure stability and functional safety.

Conveying technology: In conveying systems, they secure shafts and bolts, guarantee smooth operation of conveyor belts and minimize downtime through reliable fixation.

Packaging technology: In packaging machines, SL-retainers ensure the stable fastening of moving parts, ensuring precise and secure packaging processes.

Medical technology: Application in medical devices and apparatus where precise, stable connections are crucial to meet safety and functional requirements.

General mechanics: Used in various mechanical and technical devices to secure reliable connections that are essential for the functionality and safety of the systems.

Shaft diameter: SL-retainers are available in various sizes for shaft diameters from 4 mm to 16 mm, allowing them to adapt to different requirements.

Groove or slot: They can be used on shafts, axles, and bolts with groove or slot, making them versatile.

Integration: They are compatible with other mechanical and technical components such as bolts with groove (suitable for clevises) that feature standard dimensions and grooves.

4. Advantages and Benefits

Effective protection against axial extraction: SL-retainers offer reliable fixation with their tab that prevents shafts, axles, and bolts from being axially pulled out of their position, ensuring the safety and functionality of the connected components.

Easy installation: These retainers can be installed quickly and effortlessly, both with and without special assembly tools, simplifying the installation process and ensuring wide compatibility with various installation processes.

Play-compensating: The play-compensating feature of SL-retainers offers the advantage of compensating for tolerances and irregularities during assembly to ensure a secure and firm connection. Even with imperfectly matched components, unwanted movements and loose fits under load are effectively prevented, increasing the reliability and stability of the connection and minimizing the risk of wear or damage.

Reusability: Unlike some retainers, SL-retainers can be easily removed and reused. This reduces the need for spare parts, contributes to long-term cost savings, and guarantees flexibility and adaptability to different applications.

High-quality spring band steel: Made of spring band steel, SL-retainers offer excellent spring force and durability, making them suitable for demanding applications, providing long service life, and matching various materials and applications.

Various sizes: Available in different sizes for shaft diameters from 4 mm to 16 mm, SL-retainers are versatile for a wide range of technical requirements.

Reliable fixation: The construction of spring band steel ensures a stable and permanent connection that withstands mechanical stresses in various application areas.

Diverse application possibilities: SL-retainers are used in many industries such as mechanical engineering, automotive engineering, conveyor technology, packaging technology, and medical technology. Their versatility makes them the ideal choice for numerous applications where precise and secure connections are required.

5. Assembly and Installation

Preparation: Ensure all components (shaft, axle, bolt) are clean and free from dirt or foreign objects. This ensures safe and proper fastening. Check the dimensions of the shaft or bolt and the groove to ensure they match the size of the SL-retainer.

Tool selection: SL-retainers can be installed both with and without special assembly tools. However, for precise and efficient work, the use of an appropriate assembly tool is recommended. If no special tool is available, ensure a clean surface and use a universal plier or screwdriver to position the retainer.

Assembly with tool: Insert the SL-retainer into the assembly tool, ensuring it is properly aligned. Position the tool so that the SL-retainer is aligned straight with the groove or slot of the shaft or bolt. Push or pull the tool to set the SL-retainer into the groove. Ensure the retainer is fully seated in the groove and the retainer tab of the SL-retainer encircles the bolt end.

Assembly without tool: Hold the SL-retainer between your thumb and forefinger. Press the retainer by hand into the groove of the shaft or bolt. Ensure to apply even pressure to allow proper placement. Use pliers or a screwdriver if necessary to position the retainer and press it fully into the groove so that the retainer tab encircles the bolt end.

Post-check: Visually check the position of the SL-retainer to ensure it is fully and securely seated in the groove. Test the connection by slightly rotating or pulling to ensure everything is properly assembled.

Maintenance and readjustment: Periodically check the SL-retainers to ensure they are still securely seated and show no signs of wear or damage. If necessary, the retainer can be removed and reinstalled. Use the assembly tool or suitable aids for this.

6. Safety instructions & Standards

Safety Instructions:

- Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, to avoid injuries during assembly.

- Ensure that all parts (shaft, axle, bolt) are clean and free from debris to guarantee a secure fastening.

- Use the SL-retainers only in the designated application areas and make sure to choose the correct sizes for your specific needs.

- Regularly check the SL-retainers for signs of wear or damage and replace them as needed to ensure safety and functionality.

- Avoid applying excessive force during assembly to prevent damage to the retainer and the shaft.

Standards:

- DIN 6799: Defines dimensions and requirements for locking washers, which can also be largely applied to SL-retainers, e.g., regarding shaft diameter, groove diameter, and groove characteristics.