Job order production at mbo Osswald

Your partner for precise manufacturing solutions

Job order production

The business world is characterized by dynamism and intense competition, making flexibility an essential success factor. Companies are repeatedly challenged to efficiently utilize their production capacities while meeting the highest quality standards. In this context, contract manufacturing presents itself as an optimal solution.

mbo Osswald supports you with a comprehensive range of services in the field of contract manufacturing, to implement your production processes at the highest level. Whether for temporary projects, series productions, or custom-made single pieces – mbo Oßwald acts as a reliable partner that fulfills your requirements precisely and on time. Discover the diverse advantages of contract manufacturing with mbo Osswald and benefit from efficient and cost-saving outsourcing.

Job order production with mbo Osswald

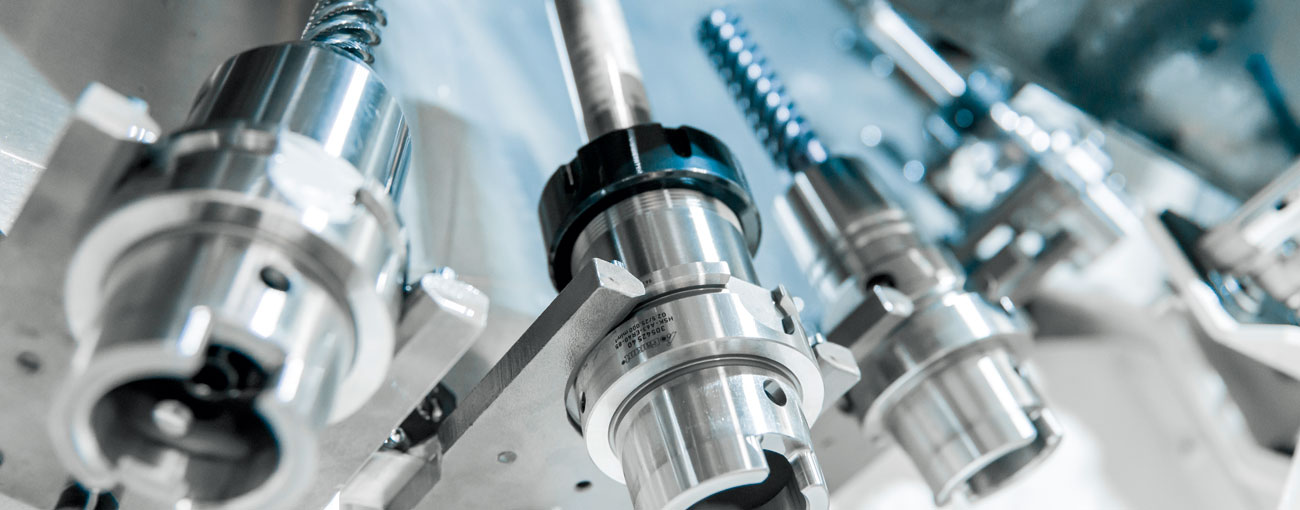

mbo Osswald offers comprehensive services in the field of job order production. With state-of-the-art technology and years of expertise, we manufacture highly precise components and assemblies according to individual specifications. Our range of services includes the production of custom parts, CNC turned parts, special screws, sleeves, sleev nuts, special nuts, threaded bolts and axles accoring to drawing. We place particular emphasis on quality, precision, and on-time delivery.

Our customers benefit from our flexibility and high technical expertise. We are capable of producing both small and large series, and we adapt our production process flexibly to the specific requirements.

Job order production, also known as contract manufacturing, describes a production process where a company – the client – delegates the manufacturing of products or components to an external company – the contract manufacturer. This approach allows the client to focus on its core competencies while benefiting from the expertise and resources of the contract manufacturer.

In Job order production, the manufacturer produces the required items according to the specifications and instructions of the client. This can include the production of complete products or individual components.

The outsourcing of production processes to a contract manufacturer like mbo Osswald has many advantages. One of the most significant benefits is cost savings. By outsourcing production, high investment costs for machinery and equipment as well as ongoing costs for their maintenance and upkeep are eliminated. This approach allows companies to use their financial resources more wisely and focus more on their core competencies, thereby optimizing the efficiency of business processes.

Another major advantage is the gained flexibility. As a contract manufacturer, mbo Osswald has comprehensive manufacturing capacities and is able to also handle short-term orders and production increases. This aspect allows companies to quickly and flexibly respond to market changes. The quality of the produced goods also benefits significantly from cooperation with a specialized contract manufacturer. Thanks to the combination of modern technologies and many years of experience, high-quality products are manufactured that meet the requirements and expectations of the clients.

The benefits of job order production by mbo Osswald:

- Cost savings

- Flexibility

- Higher product quality

- Focus on core competencies

- Faster responsiveness to market changes

- 8000 m² storage space

Job order production encompasses various processes that are applied depending on the specific requirements and specifications of the client. These methods can broadly be categorized as follows:

Machining technology

The field of machining technology includes a variety of techniques such as turning, milling, drilling, and grinding. These methods are excellent for manufacturing precise components from metals and other materials. They are particularly characterized by their high precision and reproducibility.

Forming technology

Forming techniques such as bending, stamping, and deep drawing are used to shape sheets and various other materials into the desired contours. Forming is especially used in the production of complex geometries and high volumes.

Linking technology

In linking technology, methods such as welding, soldering, and gluing are used to connect parts. It plays a crucial role in the manufacture of assemblies and demanding products.

Surface technology

Surface technology processes such as electroplating, painting, and powder coating are used to refine and protect component surfaces from corrosion and wear. Surface treatment not only improves aesthetics but also the durability of the products.

Contract manufacturing vs. job order production

Contract manufacturing and job order production represent two different approaches to production outsourcing, differing in key aspects. In contract manufacturing, the contract manufacturer provides the necessary machinery, equipment, and tools and manufactures the items according to the customer’s specifications. The customer supplies the required materials and bears the risk for their use.

In contrast, job order production involves complete production by the contractor, including material procurement. In this model, the contractor assumes responsibility for the entire production process.

|

Advantages of job order production |

Disadvantages of job order production |

|

|

|

|

|

|

|

|

|

Advantages of job order production |

Disadvantages of job order production |

|

|

|

|

|

|

Why should you order job order production parts from mbo Osswald?

Outsource processes with mbo Osswald

Take advantage of the diverse possibilities of job order production with mbo Osswald and benefit from our extensive expertise as well as advanced production technologies. Contact us today to discuss your specific requirements and develop tailored solutions for your production needs.

Additionally, we offer a wide range of standard items, which you can easily purchase through our eShop. Our assortment includes clevises, bolts, angle joints, pivoting bearings, retainers, and much more. Discover new potential and optimize your production processes with mbo Osswald.

mbo Osswald offers a wide range of services in the field of job order production. Thanks to our modern machinery, we produce workpieces with a diameter up to 65 mm and a length up to 350 mm. Additionally, we are well-equipped for the production of both small and large series, enabling us to flexibly meet the needs of our customers.

mbo Osswald offers a variety of machining options and capabilities to meet your specific requirements. The manufacturing options include:

- Cross holes: Precise holes drilled perpendicular to the axis of the workpiece

- Grooves: Targeted notches or grooves for specific functional or fit characteristics

- Milles sections: Versatile milling techniques to create complex geometries and surface structures

- Polygon turning: Production of workpieces with multiple edges for special requirements

- Spanner surface: Precise creation of spanner surfaces for easy assembly and disassembly

- Thread types:

- Metric or inch threads: We offer both to meet all international standards

- Regular, fine-pich, and left hand threads: A variety of thread types to accommodate different mechanical needs

- Complicated geometries: Production of parts with complex shapes and structures

- Custom marking: Personalized markings for the unique identification of your parts

- Modules: Assembly of components into complete modules

Through these extensive machining options, mbo Oswald can deliver custom solutions tailored exactly to your needs.

mbo Osswald has extensive expertise in handling a wide variety of materials. Regardless of specific requirements and application areas, we can manufacture components from various materials, thereby covering a wide range of customer needs.

Undercut steel

For series production on CNC lathes, free-cutting steel is optimal due to its excellent machinability. The material allows for quick and precise production of components with perfect fit and excellent surface quality. Free-cutting steel is often found in the automotive industry, mechanical engineering, and electrical engineering, where precision and cost efficiency are extremely important.

Stainless steel A2 quality

Stainless steel of the A2 grade combines corrosion resistance with high strength. The material is extremely versatile and is mainly used in the food industry, construction, and mechanical engineering. A2 stainless steel is particularly suited for components in moderately corrosive environments, where it also exhibits remarkable mechanical robustness.

Stainless steel A4 quality

The material stainless steel in A4 quality is characterized by excellent corrosion resistance, making it perfect for use in marine environments and the chemical industry. It resists chlorides and aggressive chemicals equally and has high durability and reliability. Typical areas of application include components in shipbuilding, on offshore platforms, and in chemical production sectors.

Other steels

In addition to the aforementioned materials, mbo Osswald offers a variety of steels with specific properties for different applications. These include:

- corrosion-resistant steel - optimal for use in aggressive environments

- seawater-resistant steel - resistant to saltwater

- heat-resistant steel - perfect for high-temperature applications such as in power plants

- high-strength steel - ideal for heavy loads

mbo Osswald offers a variety of surface treatments and coatings to optimally refine and protect your components. The services include:

- Coating (Various coating processes extend the lifespan and improve the performance of your components):

- Electroplated galvanised: Protective layer against corrosion through galvanic zinc coating

- Special surface: Individually adapted surface coatings for special applications

- Treatment (Different surface treatments to enhance appearance and functionality):

- Free of grease: Special cleaning for grease-free surfaces, ideal for sensitive applications

- Defined oil film: Controlled coating with a defined oil film for lubrication and corrosion protection

- Finishing (Heat treatment processes to enhance material properties):

- Grinding: Precise grinding for a smooth and accurate surface

- Tempering: Increase in surface hardness through targeted heat treatment

- Nitrocarburizing: Diffusion of nitrogen and carbon to improve wear resistance and corrosion resistance

Through comprehensive surface treatments, mbo Osswald ensures the longevity and performance of your components.