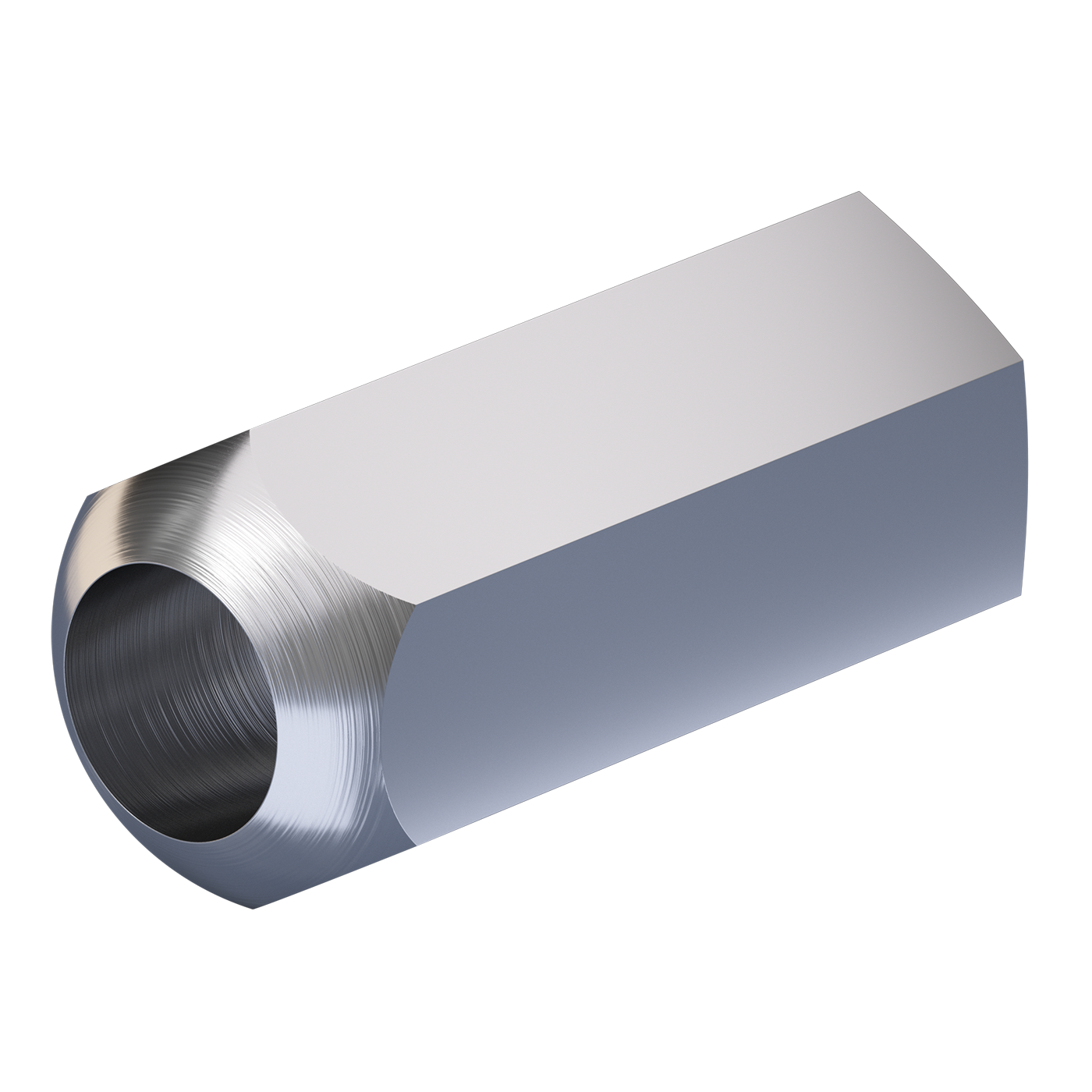

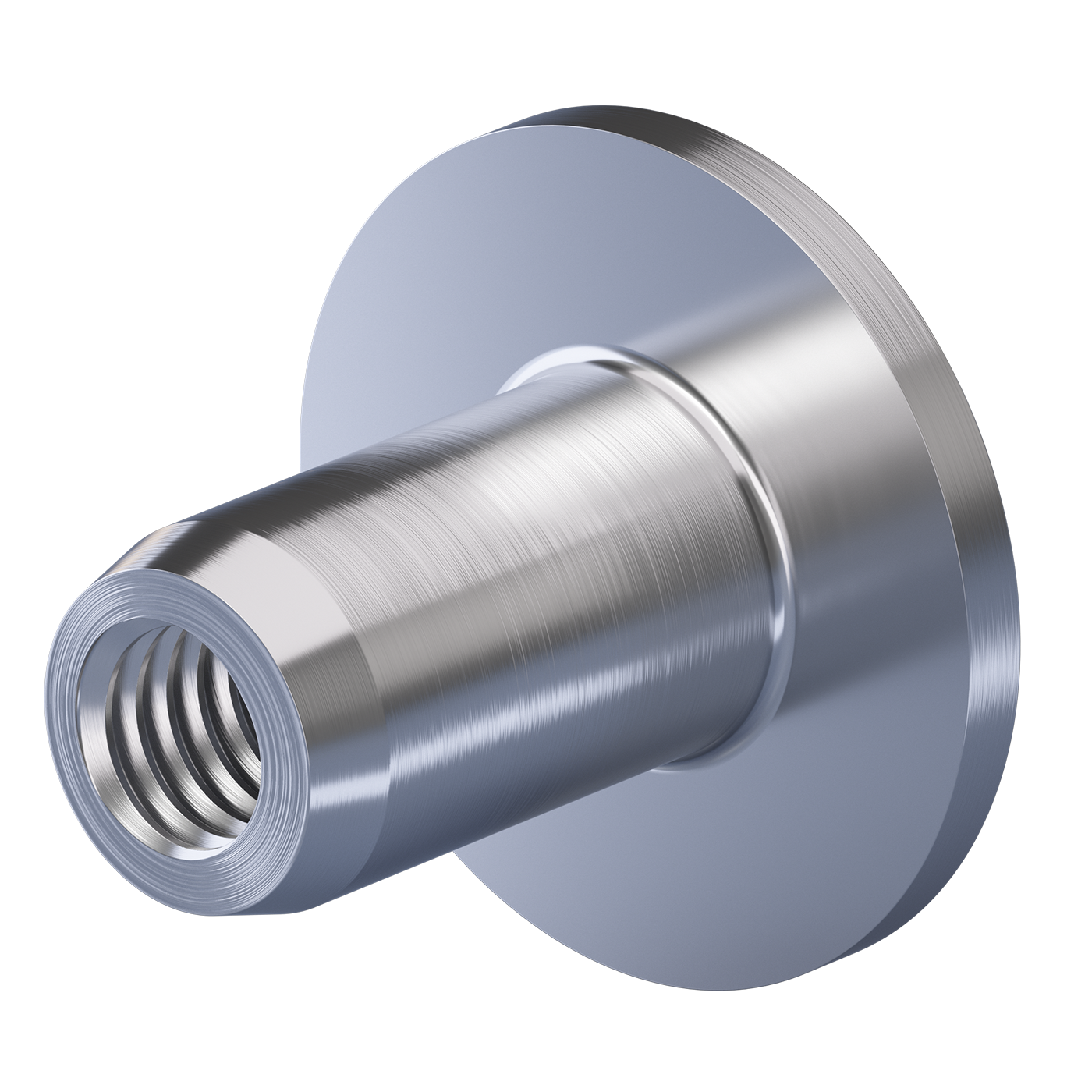

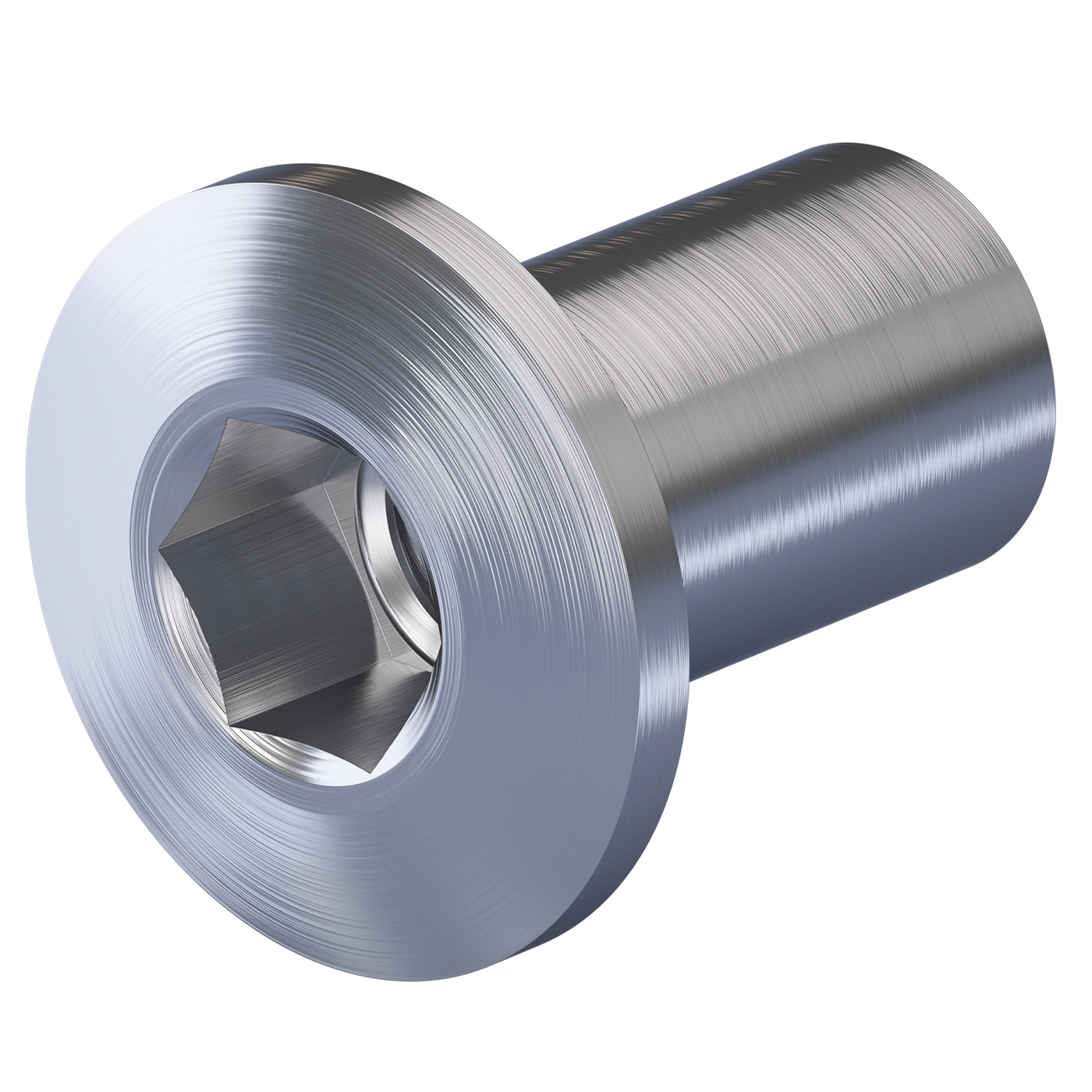

Sleeve nuts combine the properties of a spacer with those of a screw-type connector in one and the same part. The presence of the sleeve brings about considerable benefits by making it possible to achieve a precise spacing between the elements that are to be joined. At the same time, the nut that is incorporated in the sleeve provides the functionality of a conventional screw-type connector, thereby increasing the efficiency and strength of the join.

Combining the qualities of the sleeve and nut in this way brings additional advantages in terms of enhanced functionality and space savings. Sleeve nuts are the ideal solution in constructions where conventional connecting elements are no longer sufficient due to their dimensions, thread type or material.

mbo Osswald manufactures sleeve nuts to its customers’ specifications. Our production processes are tailored to the manufacture of dimensionally precise, high-quality parts.

Based on our many years of experience in the manufacture of precision turned and milled parts, we are committed to providing you with a comprehensive range of services – from meticulous detailed planning through to reliable delivery logistics. When you come to us, you benefit from high quality, absolutely precise delivery quantities and on-time supplies. Our range of services also includes additional activities such as the assembly, packaging, custom marking and professional storage of your sleeve nuts.

Range of services for custom sleeve nuts turned (extract)

Machining range |

|

Machining capabilities/options |

|

Material |

|

Surface |

|