Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

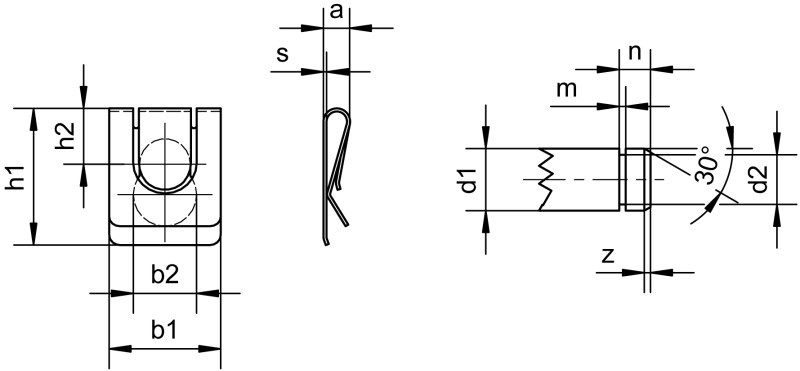

Bayonet clips are essential retainers for axles, bolts, and shafts with groove, specifically designed to prevent unwanted axial movements. They are clipped upwards onto the bolt using a precisely formed tab to ensure a reliable and secure connection. The intelligent design of bayonet clips makes it easy to place on the bolt, while the tensioned tab provides a firm grip. The clips prevent the unwanted loosening of the bolt in the axial direction, making them ideal for applications where reliable connections are indispensable.

It's important to note: This securing method is only suitable for a certain distance (= dimension "n") between the groove and the shaft end. Our bayonet clips are designed for specific distances and should be selected accordingly to the requirements on site.

One of the outstanding features of these clips is their reusability. They can be disassembled just as quickly and easily as they can be assembled, making them a cost-effective solution for repeated applications.

2. Product details

Size: 4 mbo 06 - 16 mbo 06

Material group: Steel

Surface: electr. galvanised white, phosphatised oiled

3. Application Areas & Compatibility

Bayonet clips are used in various applications, especially where reliable fixation and securing of components are necessary. Relevant application areas include:

Mechanical engineering: Bayonet clips are used here to secure axles and bolts. They ensure that components do not unexpectedly loosen during operation, thus increasing the operational safety and longevity of machines.

Electrotechnology: In this field, bayonet clips serve to securely fix housing covers or closures. This allows quick access to electronic components for maintenance or repair work without the need for special tools.

Precision mechanics: For applications requiring highly precise and secure connections, bayonet clips are ideal. They help ensure that devices function accurately and reliably by connecting mechanical parts stably.

Installation technology: Bayonet clips are used here for fastening pipelines and other installations. They offer a simple and efficient way to quickly assemble and disassemble elements as needed.

Furniture industry: In this area, bayonet clips are used for connections that allow easy assembly and disassembly of furniture pieces. This is particularly advantageous for modular furniture, which often needs to be reconfigured or transported.

Compatibility

The compatibility of bayonet clips plays a crucial role in the selection and application of these retainers. Key points regarding compatibility are:

Dimension "n": The distance between the groove and shaft end must exactly match the specifications of the clip, as this distance is critical for secure fastening.

Size and shape: The size and shape of the clip must match the dimensions of the bolt or axle to ensure secure hold. Deviations can lead to inadequate fixation.

Environmental conditions: The clips should be suitable for the specific environmental conditions under which they are to be used, such as extreme temperatures, humidity, or chemical influences.

Assembly tools: Check if special tools are required for the assembly or disassembly of the clips, and if these tools are compatible with the existing equipment.

4. Advantages and Benefits

Bayonet clips offer a variety of advantages and benefits that make them a preferred retainer in many industries:

Easy assembly and disassembly: Thanks to their special design, bayonet clips can be quickly assembled and disassembled without special tools, reducing time and labor requirements.

Reliable securing: The clips provide a firm hold that effectively prevents unwanted movement and loosening of bolts and axles, thereby enhancing the safety and stability of connections.

Reusability: An outstanding advantage is their reusability. They can be easily reused multiple times, reducing the cost of spare parts and assembly.

Compact design: Bayonet clips have a space-saving construction that allows for application in confined or hard-to-reach areas.

Universal application: They are used in various industrial sectors such as mechanical engineering, electrical engineering, precision mechanics, and medical technology, underscoring their versatility.

Cost-effectiveness: Due to their durability and reusability, they offer a cost-effective solution for repeated applications without quality loss.

5. Assembly and Installation

Preparation of the workplace: Ensure the workplace is clean and well-lit to allow for precise assembly. Have all necessary components and the bayonet clip within reach.

Safety precautions: Wear appropriate protective equipment such as gloves and safety glasses, especially when working with machinery or in environments with increased risk of injury.

Verification of measurements: Ensure that the "n" measurement (distance between the groove and shaft end) matches the bayonet clip specifications for a proper fit. The bolt diameter, as well as the diameter and width of the groove, are also crucial.

Positioning the clip: Position the bayonet clip at the groove or slot of the bolt or shaft in such a way that the tab is correctly aligned.

Securing the clip: Gently press the bayonet clip onto the bolt or shaft until the tab snaps into place, ensuring the clip is secure.

Checking the fixation: Verify that the bayonet clip is firmly in place and does not allow any unwanted movements. A secure fit is essential for the effectiveness of the fastening.

Disassembly (if needed): If the bayonet clip needs to be removed, carefully lift the tab to release the clip and then pull it off the bolt or shaft.

Wear Inspection: Regularly check the bayonet clip and the component to be secured for wear or damage to ensure safe use at all times.

6. Safety instructions & Standards

Use of protective equipment: Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against mechanical injuries or tool slippage.

Inspection before use: Inspect the clips for visible damage or wear. Damaged clips should not be used, as they may compromise the safety of the connection.

Tool usage: If tools are required for the assembly or disassembly of the clips, always use the appropriate tool to avoid damage to the clips or the parts to be secured.

Avoiding excessive force: Do not apply too much pressure during assembly or disassembly to prevent damage to the clips or attached components.

Proper storage: Store bayonet clips in a dry and clean location to avoid corrosion or contamination, which could impact their functionality.

Consider environmental conditions: In applications within special environments (e.g., corrosive or extreme temperatures), ensure that the chosen clips are suitable to prevent material failure.

Documentation and traceability: Comprehensive documentation regarding usage and maintenance should be maintained. This information helps to quickly identify and resolve potential issues.