Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

The bolt with pin hole is a versatile linking element, particularly used in combination with clevises according to DIN 71752. The pin hole aids in securing the connection by accommodating a cotter pin according to DIN 94. In practice, the bolt is guided through the symmetrical cross-hole of the clevis. The precise design of the bolt ensures accurate alignment within the joint. After inserting the bolt, a cotter pin is inserted through the pin hole to hold it securely and permanently in the designated position. The bolt can also be used in combination with washers according to DIN 125 to optimize load distribution and minimize wear on the connected components. This ensures a stable connection that reliably withstands mechanical stresses.

Bolts with pin hole are not limited to use with clevises. They are versatile fasteners used in numerous applications, such as axle mountings in vehicles and machinery, lever connections in mechanical lever systems, or in agricultural equipment.

The bolt is made from high-quality materials such as steel or stainless steel, making it suitable for use in both corrosive and heavily loaded environments. By using specialized surface coatings such as galvanization, the resistance to weather conditions is further enhanced. The standardized dimensions allow for seamless integration into existing systems, making them ideal for use in various industrial applications.

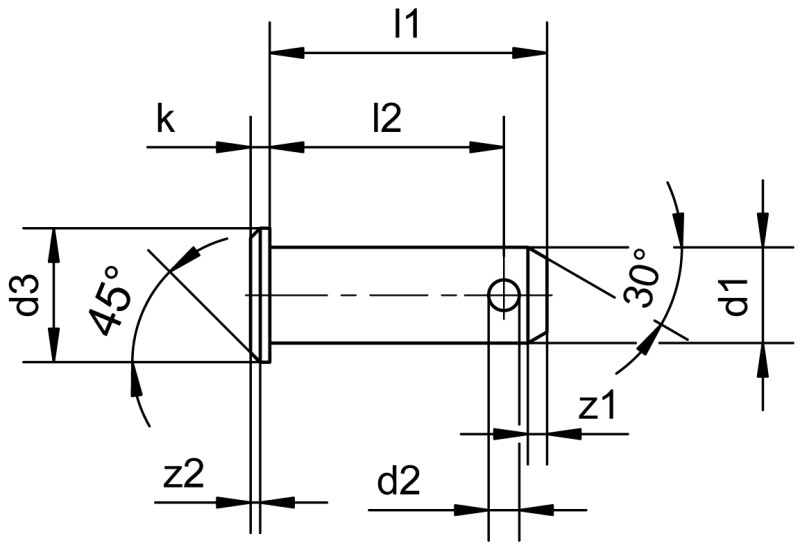

2. Produktdetails

Size: BGL 4 x 12 x 10 - BGL 50 x 115 x 103

Material group: Steel, stainless steel, stainless steel A4 quality

Surface: bright, electr. galvanised white

d1 Bolt diameter: 4 - 50

l2 Grip length: 10 - 103

3. Application Areas & Compatibility

The bolt with pin hole is a proven fastener in the industry and finds application in various fields:

Mechanical engineering: Here, the bolt is often used to connect mechanical components in production machines and conveyors. For instance, it can be used in an automated assembly line where it takes on the fixation of linear drives to guide elements. Its ability to transfer and fix movements makes it a robust choice for machines that are subject to constant stress.

Agriculture: In agricultural machinery like tractors and combine harvesters, bolts with pin hole are indispensable for the robust connection of moving parts. They are often used to connect hydraulic cylinders with control arms, allowing flexible adaptation of the equipment to changing field conditions. The pin system ensures that the connection remains secure even under strong vibrations or uneven terrain.

Construction: In construction, applications often concern heavy machinery such as excavators and cranes. The bolt is used here to securely and stably mount mobile components like buckets or lifting equipment. A practical example is the use in a hydraulic system, where it connects the swivel arms for maximum stability when loading and unloading heavy materials.

Electrical installations: In electrical and electromechanical installations, such as switchgear or transformer stations, bolts with pin hole help in the stable mounting of heavy cable trays and fastening devices that are subjected to high physical stress.

Compatibilities

Thanks to standardized manufacturing according to DIN 1434 and compatibility with clevises DIN 71752, these bolts can be flexibly integrated into various industrial systems. The standard combination with washers DIN 125 form A and cotter pins DIN 94 ensures both reliable securing and easy maintenance, as the parts are universally interchangeable and can usually be installed without special tools.

4. Advantages and Benefits

Safety and Stability: The bolt with pin hole provides a reliable security by enabling the insertion of a cotter pin, preventing unintentional loosening of the connection. This is crucial in mechanical systems that are regularly exposed to vibrations or dynamic forces. For example, in a production machine, this feature ensures that all moving parts remain securely connected, minimizing downtime and enhancing operational safety.

Assembly and disassembly: A bolt with pin hole significantly eases assembly and disassembly compared to alternative connection methods. Unlike screw connections, there is no need for threading, leading to faster and simpler handling. This not only saves time but also reduces wear on components since no direct torques need to be applied. In applications requiring frequent disassembly, the bolt proves user-friendly as the pin can be removed and reinserted with little effort, whereas screw assembly usually requires tools. Unlike welded connections, the bolt also offers flexibility and reusability, as the connection can be undone without damaging the parts.

Durability: The use of robust materials such as steel or stainless steel, often complemented by protective coatings like galvanization, significantly increases the lifespan of the bolts. These materials are resistant to corrosion and wear, which is particularly important in demanding environments, such as agricultural engineering or shipbuilding, where components must withstand both mechanical and weather-related stresses.

Cost efficiency: Standardized production allows the use of bolts with pin hole in a wide variety of applications without the need for adjustments. This reduces inventory costs and simplifies procurement. Additionally, standardized design simplifies assembly, as bolts, washers, and pins are manufactured according to common standards (like DIN 1434, DIN 94, and DIN 125) and can be quickly and securely installed without special tools.

Flexibility and adaptability: Due to their standardization, these bolts fit into a variety of systems and are easily interchangeable. When expanding or retrofitting equipment, the same bolts can often be reused without further modifications, allowing a seamless transition during changes in the production line.

These features make the bolt with pin hole a valuable component in mechanical linking technology, providing a stable, safe, and cost-efficient solution in many industrial applications.

5. Assembly and Installation

Component preparation: Before beginning the assembly of a bolt with pin hole, ensure that all components to be connected, such as bolts, washers used, or specific assembly elements, are clean and free from damage or contamination. A clean surface is crucial for the longevity and stability of the connection.

Alignment of parts: When guiding the bolt through the designated assembly openings, whether it is through a clevis's cross hole or other fastening structures, precise alignment is important. This ensures optimal support and minimizes wear on the connected parts.

Assembly of linking elements: Once the bolt is positioned, a cotter pin is passed through the pin hole to secure the connection. The cotter pin should be fully inserted through the bolt and its two ends bent to prevent it from slipping out. Optionally, washers can be added to optimize load distribution and protect the bolt.

Safety check: After assembly, the connection should be checked for a firm fit and correct functionality. This includes verifying the freedom of movement where required, and checking the correct placement of all retainers, especially the cotter pins.

Maintenance and inspection: Regular maintenance is critical for the durability of the connection. This includes visual inspection of the bolts for wear or damage, as well as checking the retainers. Lubricants should be applied as needed to reduce friction and ensure mobility.

This systematic approach to the assembly and use of bolts with pin hole ensures a stable and reliable connection that meets operational requirements and maximizes the lifespan of mechanical systems.

6. Standards and Accessories

The relevant standards for bolts with pin hole in the context of connection with clevises are:

DIN 1434: This standard defines the design and technical details of bolts with pin hole.

DIN 71752: This standard specifies the requirements for clevises, with which the bolt is used to ensure correct fit and functionality.

DIN 94: This standard covers the specifications for cotter pins used as retainers for bolts with pin hole.

DIN 125 Form A: This standard describes the requirements for washers used in conjunction with bolts to improve load distribution.

These standards ensure a standardized and reliable connection solution in mechanical systems. The accessories make bolts with pin hole adaptable for various applications where safety, stability, and ease of maintenance are crucial.