Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

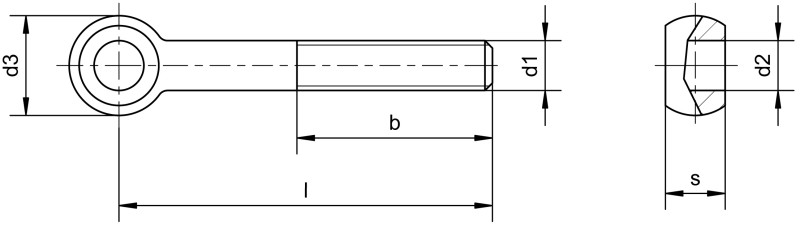

Eye bolts according to DIN 444 are high-quality fastening elements that have an eye (loop) on the screw head, which serves as a connection point for hooks, bolts, rods, ropes, cables, carabiners, shackles, and much more. Traditionally, these eye bolts are used in construction areas where a reliable and reusable fastening is needed. They are suitable for both static and dynamic loads and offer a secure connection option through the closed eye (loop). The round shape of the eye facilitates the hooking of various connection elements, making them a versatile choice for many construction and assembly tasks.

Eye bolts according to DIN 444 differ in form A, B, and C. - Form B has, however, crystallized as the standard, therefore we mainly offer form B and additionally form LB at mbo Osswald.

Eye bolts form B have a metric partial thread, which does NOT extend continuously to the eye/loop over the entire length of the screw to ensure a defined distance between the thread and the eye/loop.

In contrast, form LB offers a thread that extends over the entire length almost to the eye/loop.

Both forms, B and LB, are typically made from high-quality steel or stainless steel to ensure optimal durability and corrosion resistance. The choice of material depends on the specific requirements of the application, as well as the decision for a surface coating, which can offer additional protection against environmental influences. The standardized manufacturing according to DIN 444 ensures high quality and precise compatibility with other fastening and machine elements.

Features of eye bolts DIN 444 form A include a smaller eye diameter with a stronger eye.

The eye bolts form C differs from eye bolts form B by different shaft lengths.

In practice, mainly eye bolts DIN 1444 form B are used.

2. Product details

Size: M5x25 - M24x200

Material group: Steel strength class 4.6 (Alternatively, strength class 8.8 possible), Stainless steel

Surface: Steel: plain & galvanically zinc-plated white, Stainless steel: plain

Thread type: standard right-hand thread

d2 Hole diameter: 5 - 22

d3 Thread: M5 x 0,8 - M24 x 3

3. Application Areas & Compatibility

Mechanical and plant engineering: In these industries, eye bolts are used for fastening and positioning of machine components. Their robust construction ensures a reliable connection that is essential for the safety and efficiency of critical machine parts. Architecture and construction sector: In the construction industry, eye bolts are excellently suited for the temporary or permanent connection of components. Their load capacity makes them a safe choice for the construction of support structures, roofs, and other critical building elements. Stage and event technology: Eye bolts allow for flexible and secure suspension of stage equipment, lighting fixtures, and decorations. Their quick assembly and disassembly are particularly appreciated in the dynamic environment of events and performances.Eye bolts can be combined with a variety of fastening elements such as hooks, carabiners, or ropes, enabling their application in diverse scenarios. Their modular nature supports the development of flexible and adaptable fastening and securing systems.

4. Advantages and Benefits

The main advantages of eye bolts DIN 444 form B and LB lie in their high load-bearing capacity and versatility. The precise manufacturing according to DIN standards promises consistently high quality and reliability. Their simple, yet effective design allows for quick assembly and disassembly, saving time and costs. In addition, the wide choice of sizes offers a flexible solution for many different requirements. By using high-quality materials, they are extremely durable and resistant to mechanical stresses as well as environmental influences, which extends their lifespan.

With their long service life and the reduction of maintenance requirements, eye bolts offer an economical solution compared to less robust fastening elements.

5. Assembly and Installation

Ensure that the selected eye bolts meet the requirements of the application, including load capacity, material (e.g., steel or stainless steel), and size, and that all required components are in a flawless condition. These include the eye bolts themselves, as well as suitable nuts, washers, and, if necessary, securing elements.

The eye bolt is inserted into the designated hole. The size of the pilot hole should be slightly smaller than the outer diameter of the threaded part of the eye bolt. Then, the eye bolt is tightened. Ensure to tighten the screws evenly to guarantee an even load distribution.

If necessary, locking nuts or other securing elements can be used to protect the bolts against unintentional loosening.

Regularly check the assembly to ensure that there is no loosening or damage. This is particularly important for applications that are exposed to increased loads or extreme environmental conditions.

6. Accessories and Extensions

Additional nuts DIN 934 or DIN 439, which are applied to the thread of the eye bolts, prevent unintentional loosening. Lock nuts or self-locking nuts offer additional security against vibrations.

Washer DIN 125 form A, which lies under the head of the eye bolt or under the nut, to distribute the load over a larger area and protect the surfaces from damage.

Clevises DIN 71752 / DIN ISO 8140 can be combined with eye bolts to create pivoting connections or connection points with freedom of movement. They are useful in mechanical arrangements that require some mobility or adjustability.

Frequently Asked Questions (FAQ)

What distinguishes eye bolts form B from form LB?

What are the main advantages of eye bolts DIN 444?

What are the main advantages of eye bolts form B?

Optical aspects can also be a reason for using form B, for example, when the area without a thread remains visible in architectural applications.

What are the main advantages of eye bolts form LB?

What materials are eye bolts DIN 444 typically made of?

For which application areas are eye bolts particularly suitable?

What sizes of eye bolts are available?

How is unintentional loosening of eye bolts prevented?

Why is checking the assembly of eye bolts important?

What other elements can eye bolts be combined with to extend their functionality?

What role does material choice play in the application of eye bolts in certain environments?

How does surface coating affect the properties of eye bolts?

How is the correct load capacity of eye bolts determined for specific applications?

An important factor for the load capacity is the strength class. This determines the tensile strength and the yield strength. For steel eye bolts, the strength class 4.6 is available as an alternative to the strength class 8.8.

Can eye bolts be used for outdoor applications, and what precautions should be taken?

Can eye bolts be reused, and if so, under what conditions?

What is the difference between eye bolts DIN 444 and ring bolts DIN 580?

Eye bolts DIN 444 are primarily used for guiding or securing loads in the direction of the bolt axis. They are designed for fixings where the load mainly acts in one direction.

Ring bolts DIN 580 are particularly suitable for applications in the lifting equipment area, where loads can act from various directions. They are optimized to absorb multidirectional forces.

What is the difference between eye bolts DIN 444 and commercial screws?

Are custom-sized eye bolts also manufactured?

If you already have a drawing of your desired part or want to develop a solution together with us, do not hesitate to contact mbo Oßwald directly. We are ready to turn your ideas into reality.