Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

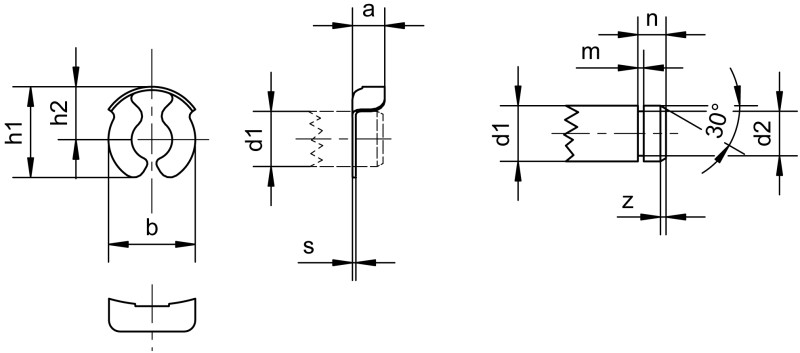

KL-retainers prevent axial pull-out on shafts, axles, and bolts with groove or slot. These retainers stand out for their ease of use: they can be installed quickly and easily without special assembly tools. Another advantage is their reusability, allowing for flexible use and long-term cost savings. KL-retainers are made from high-quality spring band steel and are noted for their excellent spring force and durability, making them ideal for demanding applications. They are available in various sizes for shaft diameters from 3 mm to 24 mm, covering a wide range of technical requirements. Due to their robust design and versatile applications, KL-retainers are frequently used in mechanical engineering, vehicle construction, and material handling technology. They ensure reliable and permanent fixation that withstands high stresses in these fields.

2. Product details

Size: 3 mbo 09 - 24 mbo 09

Material group: Steel

Surface: electr. galvanised white, phosphatised oiled

3. Application Areas & Compatibility

Mechanical engineering: KL-retainers serve to secure mechanical connections in industrial machines and equipment, providing protection against axial pullout and ensuring robust and secure connections even under challenging conditions.

Automotive engineering: These shaft retainers are used in the manufacture of vehicle components such as engines, chassis, and other critical parts to ensure stability and functional reliability.

Conveyor technology: In conveyor systems, they fasten axles and bolts, ensuring the trouble-free operation of conveyor belts and minimizing downtime through their reliable fixation.

Packaging technology: In packaging machines, KL-retainers allow for the stable mounting of moving components, ensuring precise and secure packaging processes.

Medical technology: KL-retainers are used in medical devices and apparatus where precise and stable connections are essential to meet safety and functional requirements.

General mechanics: Used in various mechanical and technical devices to ensure reliable connections that are essential for the functionality and safety of systems.

Shaft diameter: KL-retainers are available in a variety of sizes, suitable for shaft diameters from 3 mm to 24 mm, allowing them to flexibly adapt to different requirements.

Groove or slot: KL-retainers are specifically designed for use on shafts, axles, and bolts with a groove or slot.

Integration: They are compatible with other mechanical and technical components like bolts with groove, suitable for clevises, and fit standard dimensions and grooves.

4. Advantages and Benefits

Effective protection against axial pull: KL-retainers ensure reliable fixation that prevents the axial withdrawal of shafts, axles, and bolts, thus ensuring the safety and functionality of the connected components.

Easy assembly: These retainers can be quickly and easily mounted without the need for special assembly tools, simplifying the assembly process and ensuring high compatibility with different installation methods.

Reusability: Unlike some other retainers, KL-retainers can be easily removed and reassembled. This reduces the need for spare parts, leads to long-term cost savings, and offers flexibility and adaptability for various applications.

High-quality spring band steel: Made of spring band steel, KL-retainers are characterized by excellent spring force and durability, making them suitable for demanding applications. They are durable and compatible with various materials and applications.

Various sizes: The broad range of sizes for shaft diameters from 3 mm to 24 mm makes KL-retainers versatile and allows them to adapt to a wide range of technical requirements.

Reliable fixation: The manufacture from spring band steel ensures a stable and durable connection that withstands mechanical loads in various areas of application effortlessly.

Wide range of applications: KL-retainers are used in numerous industries, including mechanical engineering, automotive engineering, material handling, packaging technology, and medical technology. Their versatility makes them the optimal choice for a variety of applications requiring precise and secure mechanical connections.

5. Assembly and Installation

Preparation: Ensure that all components such as retainer, shaft, axle, or bolt are clean and free from dirt or foreign objects to ensure safe and proper attachment. Also, check the dimensions of the shaft or bolt to ensure they match the size of the KL-retainer.

Tool selection: KL-retainers can be installed without special assembly tools. However, for precise and efficient work, the use of a suitable assembly tool is recommended. For example, use a universal pliers to position the retainer.

Assembly: Hold the KL-retainer between thumb and forefinger. Press the retainer into the groove of the shaft or bolt by hand. Ensure you apply even pressure to enable correct placement. If necessary, use pliers to position the retainer and press it fully into the groove.

Post-installation check: Conduct a visual inspection of the KL-retainer to ensure it is fully and securely seated in the groove. If necessary, check the connection by gently twisting or pulling to ensure everything is correctly placed.

Maintenance and adjustment: Regularly check the KL-retainers to ensure they remain securely in place and show no signs of wear or damage. If needed, the retainers can be removed and reassembled with suitable tools (see assembly).

Following these steps ensures the KL-retainers are properly and securely installed, guaranteeing reliable fixation and longevity of the fasteners.

6. Safety instructions & Standards

Safety instructions:

- Always wear appropriate personal protective equipment (PPE) such as safety glasses and gloves to prevent injuries during assembly.

- Ensure all components such as shafts, axles, and bolts are clean and free of dirt to allow safe fastening.

- Use KL-retainers only in the designated application areas, and choose the appropriate size for your specific requirements.

- Regularly inspect the KL-retainers for wear or damage and replace them as needed to ensure safety and functionality.

- Avoid applying excessive force during assembly to prevent damage to the retainer and the shaft.

Standards:

- DIN 6799: This standard specifies the dimensions and requirements for locking washers, which are largely applicable to KL-retainers, particularly regarding shaft diameter, groove diameter, and groove characteristics.