Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

Our knuckle eyes are high-precision mechanical components specially designed for demanding connection and bearing applications. They are versatile and often used as standard connections on the piston rod of pneumatic cylinders or gas springs. In particular, the dimensions of these knuckle eyes can be designed to be exactly compatible with a clevis according to DIN 71752 / ISO 8140. Due to this compatibility, a universally usable joint with additional internal and/or external threads can be easily constructed as a connection part. Made from high-quality materials such as steel and stainless steel, our knuckle eyes offer outstanding stability and durability. Whether in automated systems or manual applications, knuckle eyes provide reliable and efficient solutions for your connection needs.

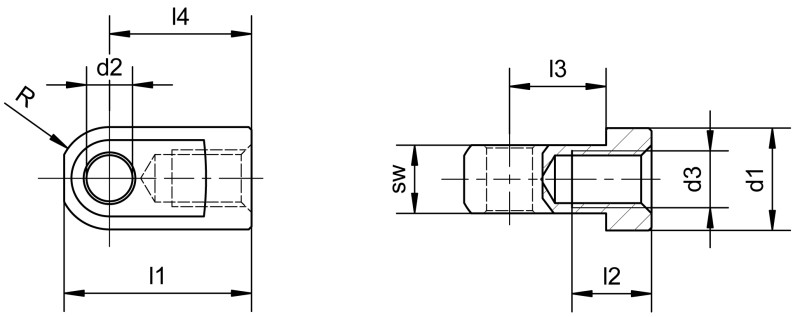

2. Product details

Size: 3,5 M3,5 - 14 M14FG

Material group: Steel, stainless steel

Surface: bright, electr. galvanised white

Thread version: Regular thread right and left, fine-pitch thread right

d1 External diameter: 8 - 25

d2 Hole diameter: 4,1 - 14,1

d3 Thread: M3,5 x 0,6 - M14 x 1,5

l1 Overall length: 16 - 51

3. Application Areas & Compatibility

Mechanical engineering: Knuckle eyes are used here to create movable connections and bearings. They enable smooth operation and ensure high load capacity in mechanical systems. They are indispensable, especially in linear and rotational devices.

Medical and rehabilitation technology: In medical devices and equipment, knuckle eyes are used for precise and hygienically safe connections. Their high quality and resistance to sterilization processes make them ideal for use in surgical robots, medical storage systems, and patient equipment.

Packaging technology: Knuckle eyes contribute to the safe and efficient handling of packaging machines in packaging technology. They provide flexibility in the movement of conveyor belts, gripper arms, and other components that require constant movement.

Vehicle construction: Knuckle eyes are used in various vehicle components. For example, in mechanisms where gas springs are used. Their high tensile and fatigue strength contributes to the safety and durability of vehicles.

Conveying technology: Knuckle eyes are essential for reliable connections in conveying systems. They enable flexible and movable connections in conveyor belts, transport carts, and automated storage systems, ensuring smooth and uninterrupted operation.

The knuckle eyes are compatible with various linking elements according to DIN standards, such as clevises according to DIN 71752 / ISO 8140. This means they can be ideally integrated into systems already tuned to similar standards. This standardization ensures that the knuckle eyes are universally applicable and can be easily combined with existing components. Thus, structurally simple but highly efficient connections can be created that meet the demands of a wide range of applications.

4. Advantages and Benefits

High load capacity: Knuckle eyes made of steel and stainless steel are characterized by their exceptional mechanical properties, ensuring long service life even under intense strain. They can withstand high tensile and compressive forces, making them ideal for demanding industrial applications.

Corrosion resistance: The stainless steel variants of knuckle eyes offer excellent protection against rust and chemical influences. This makes them particularly suitable for use in moist or aggressive environments, such as maritime applications or the chemical industry.

Low maintenance: Thanks to their robust construction, knuckle eyes require only minimal maintenance. High-quality materials and precise manufacturing reduce wear and extend intervals between maintenance, thus saving operating costs and reducing downtime.

Easy installation: Due to standardization and compatibility with DIN standards, installing knuckle eyes is straightforward, reducing assembly effort and installation time.

Precision: The high manufacturing precision of knuckle eyes ensures a perfect fit and high reliability in operation. This guarantees precise movements and connections, which are indispensable in precise applications, such as in automation or medical technology.

Flexibility: Knuckle eyes can be used in a wide range of applications and are compatible with many types of connections. This allows their use in different industries and systems without extensive modifications. Their compatibility with DIN standards further extends their applicability and facilitates integration into existing constructions.

5. Assembly and Installation

The installation of the knuckle eyes is straightforward and does not require any special tools. Here are some steps:

Preparation: Check the connections and threads for cleanliness and integrity to ensure a smooth installation.

Assembly: Screw the knuckle eye firmly onto the prepared male thread (e.g., on the piston rod of a gas spring) until it sits securely. Make sure to adhere to the correct torque.

Correction: Ensure that the knuckle eye is properly aligned. It should be positioned parallel and without tilting on the male thread.

Check: After installation, check the connection for a firm and secure fit. Tighten if necessary.

6. Safety instructions & Standards

Safety inspections: Before each use, knuckle eyes should be carefully checked for visible damage, such as cracks, deformations, or corrosion, as well as for signs of wear. If damage or wear is detected, the affected parts should be replaced immediately to minimize the risk of failures and accidents.

Load limits: It is essential not to exceed the load limits. Each knuckle eye is designed for a specific maximum load. Exceeding these limits can lead to material failure and structural damage. To ensure that load limits are observed, loads should be regularly checked and documented.

Proper storage: Knuckle eyes should be stored under suitable conditions, i.e., in a dry, clean environment, to prevent corrosion and dirt accumulation. Improper storage can impair material properties and compromise safety during use.

Regular maintenance: In addition to visual inspection, knuckle eyes should be regularly checked as part of maintenance schedules. Movable parts need lubrication and functionality testing. Regular maintenance ensures that knuckle eyes retain their full performance capacity.

Proper installation: It is important that the installation of knuckle eyes is carried out by qualified personnel. Incorrect assembly can lead to improper seating and uneven loading, which compromises the safety of the entire construction.

Use of appropriate tools: Proper tools should be used for both installing and removing knuckle eyes. Incorrect tools can damage threads or improperly fasten the component, compromising safety.