Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

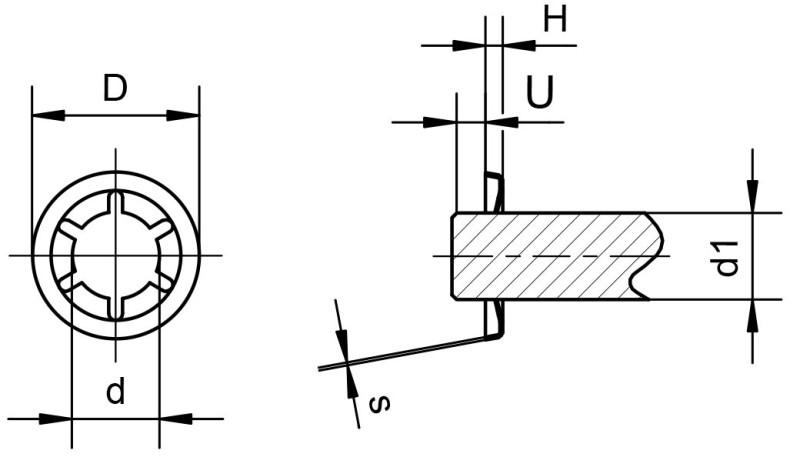

Spring washers are essential retainers for axles, bolts and shafts without groove. They are made from high-quality spring steel or stainless steel and effectively prevent axial pull on bolts and shafts. The spring washers have a convex inner shape with several slits and a spring-like property. This shape ensures that the washer exerts pressure when mounted on the shaft or bolt in a stressed condition, keeping the clamped parts securely in place. In our range, you will find spring washers for shaft diameters from 1.6 to 25 mm, suitable for a variety of industrial applications. Thanks to their robust materials, they are characterized by durability and corrosion resistance. The assembly is straightforward and requires minimal preparation. Special assembly tools are available to make the installation even easier. These tools allow for a precise and time-saving installation. Spring washers are versatile and perfectly suitable for mechanical engineering, vehicle technology, and many other fields. With our products, you ensure a reliable and cost-effective solution for fastening components on axles, bolts, and shafts without groove.

2. Product details

Size: 1,6 mbo 28 - 25 mbo 28

Material group: Steel, stainless steel

Surface: bright, varnished, mech. galvanised white

3. Application Areas & Compatibility

Spring washers for axles, bolts and shafts without groove are used in a wide range of applications. There are some relevant points regarding compatibility that should be considered:

Areas of application

Mechanical engineering: Spring washers are often used in machines to securely fix components and prevent axial movements. They are employed in both large machinery and fine mechanical devices. Spring washers are often part of standard components for various types of machinery to securely mount parts without extensive processing.

Automotive engineering: In automotive technology, spring washers are used in various components, such as securing axles, shafts, joints, or control mechanisms.

Agricultural and construction machinery: Spring washers are also used as retainers in heavy agricultural and construction machinery to ensure a solid hold under heavy use.

Electronics: Spring washers are used to secure electrical connections and fix mechanical parts in electrical devices, especially where there are no grooves.

Compatibility

Material of the bolt or shaft: The material from which the bolt or shaft is made can influence the choice of spring washer. In corrosive environments, stainless steel is recommended.

Diameter: Spring washers should be chosen to match the diameter of the shafts or bolts, as they can only perform their intended securing function then.

Axial load: The spring washers must be suitable for the respective axial load.

Operating temperature: In applications with extreme temperature ranges, the material of the spring washers must be considered to ensure their functionality is not compromised.

4. Advantages and Benefits

Advantages

Easy assembly: Spring washers are easy to assemble as they do not require any special grooves or other elaborate preparations on the shaft or bolt.

Cost efficiency: Due to their simple design, spring washers offer a cost-effective solution for retaining components.

Corrosion resistance: If made from stainless steel, spring washers offer high corrosion resistance, making them suitable for use in damp or corrosive environments.

Versatility: They are available in various sizes and materials, making them suitable for a wide range of applications and environments.

Low maintenance: Spring washers require little maintenance, especially when made from high-quality materials resistant to wear and corrosion.

Benefits

Effective axial retention: They reliably prevent the axial slipping of components on shafts or bolts, enhancing the operational safety of machines and devices.

Protection against loosening: Spring washers reduce the risk of unintended loosening of connections, which is crucial in applications with vibrations or dynamic loads.

Space-saving: Since they are directly placed on the shaft or bolt, spring washers require little additional space, making them ideal for tight or complex constructions.

Diverse applications: Thanks to their adaptability, spring washers can be used in various industries.

5. Assembly and Installation

Selection of the right spring washer: Choose a spring washer that is suitable for the diameter of the shaft or bolt. The inner diameter of the washer should be slightly smaller than the diameter of the bolt or shaft to ensure a snug fit. Ensure that the material of the spring washer is appropriate for the specific environmental conditions, especially in corrosive environments or high temperatures.

Preparation of the mounting surface: Ensure that the surface of the shaft or bolt is clean and free from dirt or lubricants. A clean surface ensures optimal friction resistance.

Positioning: Place the spring washer on the end of the shaft or bolt so that the convex inner part lays evenly. Note that the spring washer exerts axial pressure on the adjacent components to ensure their secure fixation.

Compression: Bring the adjacent components into the desired position, applying even pressure to compress the spring washer and push it onto the shaft or bolt. Ensure that this pressure is enough to create a secure connection but not so strong as to permanently deform the washer. The use of the appropriate assembly tool can be very helpful here.

Check for secure fit: After assembly, check that all parts are firmly and securely in place. Pay attention to consistent pressure across the entire contact surface of the spring washer. If necessary, perform a functional test where dynamic and static loads are simulated to confirm the secure fastening.

Correct assembly not only ensures the optimal functioning of the spring washer but also extends its lifespan and contributes to the overall safety of the application.

6. Safety instructions & Standards

When using spring washers for axles, shafts and bolts without groove, it is important to consider both safety precautions and relevant standards to ensure safe and compliant use. Here are some essential safety tips:

Quality control: Only use spring washers that are visibly free of defects. Especially in critical applications, components with flawless surface quality should be used.

Mechanical load: Avoid overloading the spring washers. Damaged or heavily deformed spring washers do not provide the necessary locking effect and should be replaced immediately.

Corrosion protection: In applications in humid or aggressive environments, you should use spring washers made of corrosion-resistant materials, such as stainless steel, to prevent failure due to rust.

Regular inspection: Regularly check the spring washers for wear or damage, especially in applications with strong vibrations or dynamic loads.

Use of appropriate tools: Use appropriate tools for assembly and disassembly to avoid damaging the spring washers and adjacent components.