Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

Ball sockets DIN 71805 form B are essential components in industrial mechanics, ensuring flexible and reliable power transmission. These components are designed to provide precise guidance and support for ball studs according to DIN 71803.

Ball sockets DIN 71805, combined with ball studs according to DIN 71803, form the angle joints according to DIN 71802.

Ball sockets allow movement on multiple axes, significantly enhancing the flexibility and mobility of mechanical connections.

This is especially important in applications where high dynamics and adaptability of the components are required, such as in robotics, automation technology, or mechanical engineering.

The ball socket is available in two different standard versions:

form A comes with a snap ring but without a groove. Additionally, a spanner surface can be attached to the socket.

For form B with a groove for mounting a circlip, a spanner surface can also be added, or it is available in the long version. The form B of DIN 71805 is specifically designed with the circlip to provide a particularly robust and resilient connection. This form is crafted to withstand both static and dynamic loads, ensuring reliable performance over long periods.

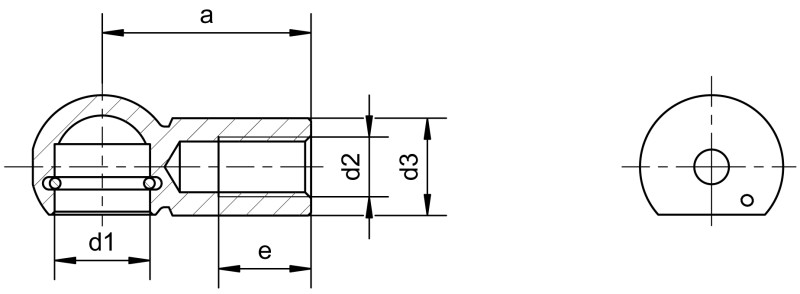

2. Product details

Size: B 8 M5 - B 19 M16

Material group: Steel, stainless steel, stainless steel A4 quality

Surface: bright, electr. galvanised white

Thread version: Regular thread right and left, fine-pitch thread right

d2 Thread: M5 x 0,8 - M16 x 2

Options

Thread: Generally, the standard versions of the ball socket come with a right-hand thread. Each size is assigned a corresponding thread size according to the standard. If the part geometry allows, different thread sizes or a metric left-hand thread are also possible as deviations from this. Additionally, for applications requiring more precise adjustment, the component can be designed with a corresponding fine-pitch thread with a lower thread pitch.

Hardened Socket: A hardened ball socket increases wear resistance. The socket gains increased durability from the hardening process. This extends the lifespan, especially in arduous and demanding applications.

Similar to DIN 71805: Ball sockets with slit and two variants made from plastic (with and without clamping bracket) are similar to DIN 71805, thus complementing the standard versions of the ball sockets.

3. Application Areas & Compatibility

Mechanical engineering: Ball sockets according to DIN 71805 form B play a key role in mechanical connections that require high mobility and adaptability. They enable precise movement transmission and are therefore essential in various machines, from simple mechanical devices to complex production equipment.

Automotive construction: In vehicles, they are commonly found in steering and suspension systems or gas springs. Their ability to facilitate precise movements ensures optimal control and stability of the vehicle, significantly contributing to safety and driving comfort.

Robotics: Ball sockets according to DIN 71805 form B also play a significant role in robotics. They are particularly relevant here due to the high demands on flexibility, precision, and load capacity that robotic systems place on mechanical components.

Railway industry: In this sector, linking elements must withstand extreme and sustained loads. Ball sockets conforming to DIN 71805 form B are ideal because they can accommodate both static and dynamic forces. Their robustness makes them a reliable component in railway equipment where vibrations and shocks are common.

Agricultural and construction machinery: Here, the requirements for mechanical connections are even higher, as these machines often operate in harsh environments and must meet high demands for load capacity and durability. Ball sockets provide the necessary robustness and flexibility to withstand these conditions.

Medical and rehabilitation technology: In medical technology, precise movement systems are essential. Ball sockets are used in devices that need to perform highly accurate and reliable movements, such as in surgical instruments or diagnostic equipment. Their high precision and reliability help ensure that medical systems operate efficiently and safely.

The general compatibility of ball sockets according to DIN 71805 form B allows for their versatile use in various mechanical and industrial applications. Their standardized dimensions and connections contribute to them being seamlessly combinable with other standardized and specifically adapted fasteners. Here are some of the explicitly compatible products and elements:

Ball studs according to DIN 71803: Ball sockets according to DIN 71805 form B are specifically designed for use with ball studs according to DIN 71803 form B and form C. This combination allows for a precise and stable corner connection that withstands both static and dynamic forces.

Rod ends according to DIN ISO 12240-4 (DIN 648): In many applications where movable connections are required, rod ends according to DIN ISO 12240-4 (DIN 648) are used. These are often compatible with ball sockets according to DIN 71805 form B, providing a flexible and robust connection solution.

Threaded rods and tie rods: In mechanical systems where precise movement and uniform force transmission are crucial, threaded rods and tie rods are often used, which can be combined with ball sockets according to DIN 71805 form B. This includes both standardized and customized components.

Custom designs: mbo Osswald also offers the possibility to develop custom designs that are tailored to the customer's requirements. These can be combined with ball sockets according to DIN 71805 form B to create bespoke solutions for specific applications.

4. Advantages and Benefits

Advantages

Precision: Ball sockets DIN 71805 form B allow for precise movements and positioning. This is particularly important in applications where exact motion sequences are required, such as in mechanical engineering.

Load capacity: They are designed to withstand both static and dynamic forces, making them robust and durable even in demanding applications like automotive or agricultural machinery.

Corrosion resistance: When made from stainless steel, these ball sockets are also suitable for use in moist or aggressive environments, such as those found in marine or chemical industries.

Standardized dimensions: The standardization according to DIN 71805 form B ensures uniform quality and compatibility with other standardized linking elements, facilitating integration into existing systems.

Easy maintenance and replacement: Due to their standardized dimensions, ball sockets can be easily replaced in case of wear or damage, which simplifies maintenance and repair.

Benefits

Improved reliability of systems: The use of ball sockets DIN 71805 form B increases the reliability of mechanical systems. They minimize the risk of mechanical failures and contribute to a longer lifespan of the entire construction.

Reduction of downtime: The robust design and easy maintenance help to minimize downtime, leading to higher availability in applications and improved overall productivity.

Cost savings: Due to their long lifespan and low need for frequent maintenance, ball sockets DIN 71805 form B contribute to cost savings. Additionally, the standardization enables cost-effective procurement and storage.

Versatile applications: Due to their versatile standard designs, they can be used in a wide range of applications, from general mechanical engineering to medical technology and specialized industrial applications.

With these various advantages and benefits, ball sockets DIN 71805 form B are an essential component of many technical and industrial systems that depend on precise, flexible, and robust mechanical connections.

5. Assembly and Installation

The correct assembly and installation of ball sockets according to DIN 71805 form B is crucial for their functionality and longevity. A precise and careful approach helps to ensure optimal performance and safety. Here are the steps for assembly and installation:

Preparation

- Inspection of the part: Before assembly, it should be ensured that the ball socket does not show any damage. Any dirt or contaminants should be removed.

- Necessary tools: For assembly, suitable wrenches, torque wrenches, and possibly special tools are generally required to ensure proper installation.

Assembly

- Preparation of connection components: The matching ball studs (DIN 71803) or other linking elements, such as threaded rods, should also be checked for integrity. They must be clean and free of damage or deformations.

- Inserting the ball socket: The hole of the ball socket with the snap ring inside is slipped over the ball of the associated ball stud. It is important to ensure this is done with even pressure and without tilting to avoid any damage.

- Fastening: Depending on the construction of the assembly, the ball socket is either fixed by screwing or another fastening method. It is important to adhere to the specified torque to ensure an optimal connection.

Adjustment and fine-tuning

- Alignment: After fastening, it should be checked whether the ball socket is adjusted in the desired position and direction. Minor corrections may be made if necessary to ensure accurate alignment.

- Test run: Before final use, the installed ball socket should undergo a test. This checks if all movements can proceed smoothly.

Maintenance and inspection

- Regular check: It is advisable to regularly check the ball sockets for their condition. In particular, the fixings and ease of movement should be controlled.

- Lubrication: If necessary, the ball sockets should be lubricated regularly to ensure a long service life and optimal function.

Replacement and repair

- Replacement in case of wear: Should signs of wear be detected, a timely replacement of the ball socket is necessary. Due to the standardized dimensions, a replacement ball socket can be easily procured and mounted.

- Compliance of spare parts: When choosing replacement ball sockets, it is important to ensure that they also comply with the specifications of DIN 71805 form B to ensure compatibility.

6. Safety instructions & Standards

When using ball sockets DIN 71805 form B, it is important to observe certain safety instructions and comply with the applicable standards. This ensures not only the optimal function of the components but also the safety of users and the entire system environment.

Safety instructions

Inspection before use:

- Before installation, each component should be checked for damage.

- Components should be free of contaminants that could impair their function.

Correct installation:

- Ball sockets must be installed according to the manufacturer's assembly instructions to ensure proper functioning.

- Ensure that the specified torque for screw connections is adhered to.

Observe load limits:

The specified load limits must not be exceeded in either static or dynamic operation to avoid material failure.

Avoid unauthorized applications:

Ball sockets are designed for specific applications and should not be used in environments or under conditions not covered by the specifications.

Regular maintenance:

- Carry out regular inspections to ensure the ball sockets are in good condition and free from wear.

- Apply proper lubrication if necessary to extend service life.

Important standards

DIN 71805: This standard specifies the requirements for ball sockets concerning their dimensions, materials, and mechanical properties.

DIN 71803: Ball studs DIN 71803 are the essential counterparts to ball sockets DIN 71805. The standard defines all critical dimensions and technical details for this accessory item.

ISO 9001 (Quality Management Systems): The manufacture of ball sockets should occur under a certified quality management system according to ISO 9001 to ensure consistent quality and reliability.

These safety instructions and standards are fundamental to ensuring the reliability and longevity of ball sockets DIN 71805 form B while safeguarding users and machinery. Adhering to these guidelines helps minimize potential risks and maximize the performance of the components in their respective applications.