Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

A clevis joint (DIN 71751 form A) is a mechanical linking element. This type of joint enables the transmission of movements and forces between two components, which can be arranged at an angle to each other. The term "DIN 71751 form A" refers to an original standard and a resulting design of this linking element. Clevis joints (DIN 71751 form A) typically consist of a clevis DIN 71752 / DIN ISO 8140 / CETOP RP102P, a bolt with pin hole, as well as a washer DIN 125 form A and a cotter pin DIN 94. This construction allows the joint to pivot around the axis of the bolt, making rotational movements within a specific angular range possible. Clevis joints are characterized by their robustness and their ability to transmit both tensile and compressive forces. They are manufactured from various materials, including steel and stainless steel, to meet the requirements of different applications and environments, such as those demanding high corrosion resistance. Furthermore, due to their standardized specifications, they offer excellent adaptability, which contributes to simplified inventory management and a reduction in storage costs. Because of this unique combination of precision, reliability, and flexibility, DIN 71751 clevis joints are an indispensable component in modern machine and plant design.

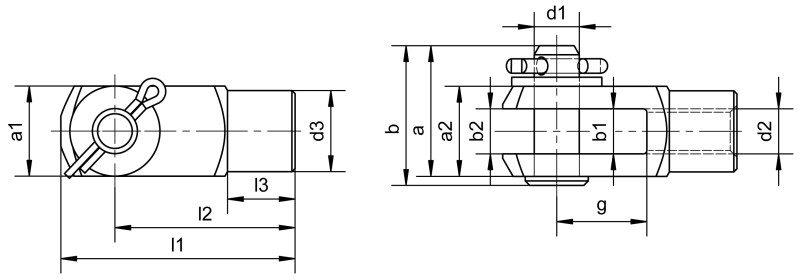

2. Product details

Size: A 4x8 M4 - A 50x96 M48

Material group: Steel, stainless steel A2 quality, stainless steel A4 quality

Surface: bright, electr. galvanised white

l1 Overall length: 21 - 265 mm

d2 Thread size: M4 x 0,7 - M48 x 5

3. Application Areas & Compatibility

Mechanical engineering and plant construction: A-joints are frequently used in mechanical design to connect movable parts. Their ability to transfer loads in different directions makes them ideal for use in machines that need to perform complex movements.

Robotics and automation technology: A-joints play an important role in modern robotics and automation, where they are essential for achieving precise movements and handling tasks. Their flexibility and reliability support the development of innovative solutions in this rapidly growing field.

Agricultural technology: In agricultural machinery and equipment, A-joints ensure the necessary freedom of movement and power transmission. Their robustness guarantees high performance even under harsh conditions and extreme weather influences.

Compatibility:

The standardized design according to DIN 71751 allows for the universal compatibility of A-joints with a variety of mechanical systems and components. Their availability in different materials such as steel and stainless steel, as well as in various sizes and designs, ensures that the right A-joint is available for almost every requirement and application area. Overall, clevis joints (DIN 71751 form A) offer a reliable and versatile solution for motion and power transmission problems across a wide range of industries and applications, with their standardized compatibility simplifying integration and maintenance.

4. Advantages and Benefits

Standardized quality: The manufacture of clevis joints (DIN 71751 form A) ensures high standardization and quality. This guarantees consistent performance and reliability for all joints.

High load capacity and longevity: Thanks to their robust construction, A-joints are capable of functioning reliably under high loads and in demanding operating environments. This increases the operational safety and lifespan not only of the individual component but also of the entire mechanical system.

Flexibility in application: The availability of A-joints in various materials like steel and stainless steel as well as in a variety of sizes and versions makes them a versatile solution for diverse requirements.

Easy installation and maintenance: A-joints are designed to allow quick and uncomplicated assembly and disassembly. This reduces effort for installation, maintenance, and repairs, enhancing the overall efficiency of the mechanical system.

Optimal motion guidance: With their special design, A-joints enable precise guidance of movements within a defined angular range. This is especially important in applications where accuracy and control over movement processes are crucial.

Corrosion resistance: The selection of clevis joints (DIN 71751 form A) in corrosion-resistant materials such as stainless steel A2 quality or stainless steel A4 quality expands their applicability to environments with high corrosion risks. This contributes to the longevity and reliability of the product, particularly in harsh or chemically aggressive work environments.

5. Assembly and Installation

The assembly of a clevis joint (DIN 71751 form A) is generally a straightforward process that must be carried out carefully to ensure a safe and effective connection.

Step 1 - Component check: Ensure all parts of the clevis joint, including the clevis, the bolt, as well as cotter pin DIN 94 and washer DIN 125 form A are present. Inspect the parts for damage, deformation, or corrosion that could hinder functionality.

Step 2 - Assembly: Screw the clevis onto the male thread of the component to be connected so that the holes of the cross hole are aligned for the bolt. A nut DIN 934 or DIN 439 can be used to secure the clevis on the male thread. Next, pass the bolt through the aligned holes in the clevis and the component to be connected, e.g., a mating piece for clevises. Ensure the bolt enters evenly and is correctly positioned on both sides. Secure the bolt to prevent loosening during operation. This securing is done using the washer DIN 125 form A and the cotter pin DIN 94.

Step 3 - Inspection: After assembly, perform a function test to ensure that the clevis joint moves as intended and is correctly assembled. Check for unwanted play or movement.

It is essential to conduct regular checks after the initial startup to verify if the linking elements have loosened or show signs of wear.

6. Standards

DIN 71751 Form A: This original standard defines requirements and dimensions for clevis joints. It provides guidelines for the production and evaluation of such joints.

DIN 71752 / ISO 8140: Similar to DIN 71751, these national and international standards specify the requirements for clevises, which in combination with bolts, washers, and cotter pins form the actual clevis joint.

DIN EN ISO 9001: This standard relates to quality management systems and is relevant for the production and quality assurance of mechanical linkin elements. It ensures that products consistently meet high quality standards.

DIN 125 Form A: DIN 125 specifies washers, often used with bolts and nuts. Form A refers to washers without a chamfer. These washers are available in various sizes for different bolt diameters and are used to distribute the load pressure of a nut or bolt head over a larger area, reducing the risk of damage to the fastening material.

DIN 94: Cotter pins DIN 94 define the dimensions and requirements for cotter pins used as retaining elements in mechanical connections. Cotter pins are simple but effective means of securing bolts and other fasteners, preventing the loosening of nuts and the falling out of bolts.

7. Accessories and Extensions

For clevis joints (DIN 71751 form A), a wide range of accessory and expansion options are available to increase their functionality and application scope. These include, among others, nuts DIN 934 and DIN 439 or clevis joints (similar to DIN 71751 form A) with additional thread, enabling longer life and improved performance.