Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

Folding spring bolts, also known as ES-bolts or snap spring bolts, are characterized by providing quick locking and unlocking of mechanical linkings. They are an important part of functionality and safety, especially when used in combination with clevises according to DIN 71752 / DIN ISO 8140.

At the core of a folding spring bolt is a spring-loaded mechanism that ensures the bolt remains fastened until manual pressure is applied. This feature not only simplifies the assembly process but also increases the overall safety and reliability of the connection. Designed to fit precisely into clevises, these bolts facilitate a swivel connection between two parts, allowing a combination of movement and stability that is essential in many mechanical systems.

Together with the clevis, the folding spring bolt forms a clevis joint and enables quick and tool-less assembly or disassembly of the joint.

A special variant of these bolts are folding spring bolts with groove. This version features a precisely machined groove on the shaft of the bolt, providing an additional locking layer. The groove interacts efficiently with the spring-loaded mechanism, enabling a more secure and stable connection.

The use of folding spring bolts is particularly advantageous where a reliable, yet temporarily detachable connection is required.

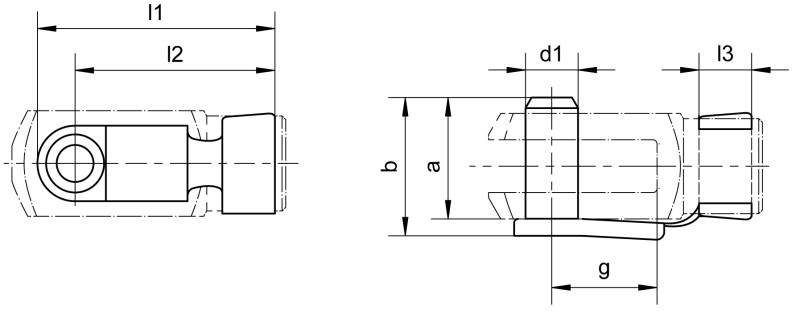

2. Product details

Size: FKB 4x8 - 20x40

Material group: Steel, stainless steel

- Steel version: Bolt made of undercut steel and spring made of spring band steel

- Stainless steel version: Bolt made of stainless steel and spring made of spring band steel

Surface: bright, electr. galvanised white, phosphatised oiled

Suitable for clevises: G 4x8 - G 20x40

d1 Bolt diameter: 4 - 20

3. Application Areas & Compatibility

Types and dimensions of folding spring bolts

Folding spring bolts come in several types and dimensions, each serving specific needs. Understanding the differences between these types is crucial for selecting the right bolt for your application to ensure both a perfect fit and optimal performance.

The material options for folding spring bolts vary, ranging from stainless steel to undercut steel, as well as specialized alloys for increased corrosion resistance and strength. The selection should be based on the environmental conditions the assembly will be exposed to, such as humidity, chemicals, or extreme temperatures, which could influence the risk of corrosion or material degradation. Stainless steel bolts are widely preferred due to their durability and rust resistance, making them ideal for outdoor use or harsh environmental conditions. On the other hand, undercut steel is often chosen for its strength and cost-effectiveness, suitable for applications where environmental exposure is minimal. It is important to note that the spring element of the folding spring bolt is always made of spring band steel.

Regarding dimensions and specifications, folding spring bolts are available in a variety of sizes to accommodate different clevis sizes and load requirements. The dimensions typically include the bolt's diameter and length, which are critical factors for the bolt's load capacity and suitability for specific clevis applications.

Selecting the right folding spring bolt for your clevis

When selecting a folding spring bolt, the dimensions play a critical role. It is essential that the bolt's dimensions match those of the clevis to ensure a secure fit. An incorrect size can lead to loose connections, increased wear, or even mechanical system failure. Technical drawings or dimension tables in the eShop can help in selecting a bolt with the correct size and fit.

An additional factor to consider is the load capacity. The bolt must be capable of handling the mechanical loads of the application without failure. This includes both static loads as well as potential dynamic forces that could cause wear or fatigue.

4. Advantages and Benefits

Folding spring bolts offer a variety of advantages over traditional fastening methods. They are designed for use with clevises DIN 71752 / DIN ISO 8140 and are essential in applications where quick and efficient connections are necessary without sacrificing strength or reliability. Their unique design allows for easy assembly and disassembly by hand. To detach the spring sling from the clevis, a flat-head screwdriver can also be used. This makes the folding spring bolt a preferred solution in areas such as mechanical engineering, construction, special vehicle manufacturing, and agricultural equipment.

Another noteworthy advantage is the construction of folding spring bolts as single-piece components. Compared to conventional fasteners, such as a combination of bolt, washer, and cotter pin or bolt with retaining rings, this significantly simplifies the assembly process. It eliminates the need to handle multiple small parts, minimizing the risk of loss or incorrect assembly. Additionally, folding spring bolts are characterized by their extremely low noise generation. In environments where noise is a critical factor, these bolts offer an excellent solution to minimize noise levels. This feature is especially beneficial in noise-sensitive areas such as office buildings, hospitals, or schools.

Mechanical Engineering: In mechanical engineering, folding spring bolts offer an unparalleled advantage in the maintenance and assembly of equipment. By simplifying the process of securing machine components, they reduce downtime and labor costs associated with equipment maintenance. Their robust construction can handle high load capacities, a critical factor in industrial machines that experience constant stress and use.

Construction: The construction industry benefits from the versatility and strength of folding spring bolts, particularly in modular construction or structures requiring temporary yet secure fastening. These bolts can quickly connect parts, significantly reducing construction times and increasing on-site efficiency. Moreover, their easy handling allows for rapid adjustments or disassembly, facilitating the recycling or reconfiguration of building materials.

Special vehicle construction: Their strength and durability ensure a reliable fastening solution that can withstand vibrations and dynamic loads typical of vehicle applications. This reduces the risk of component failure and increases the overall safety of the vehicle.

Comparative analysis: Folding spring bolts vs. traditional bolts

Beginning with ease of installation, folding spring bolts are designed for quick and straightforward assembly. Unlike traditional bolts, which may require additional tools and time for secure fastening, folding spring bolts incorporate a spring mechanism that allows them to be quickly inserted and locked without extensive tightening, making them particularly useful in applications where time and ease of installation are critical.

Considering the load capacity, folding spring bolts provide a robust fastening solution. While traditional bolts can handle significant loads, especially when properly secured with washers and cotter pins or locking washers and retaining rings, folding spring bolts offer comparable strength with the added advantage of a locking mechanism that prevents loosening under vibration or dynamic loads. This feature ensures secure fastening even in applications exposed to high movements or loads, making them highly reliable for various industrial uses.

It should be noted here that the use of screw connections is merely an optional variant that is applied when a firm clamping is required and/or the joint combination should no longer be easily undone without tools. However, more common are the various joint variations that mbo Osswald offers, which are designed for a wide range of applications where flexibility and reliability are paramount.

Durability is another crucial factor in comparison. Traditional bolts, depending on the material, can demonstrate high strength and resistance to environmental factors. Folding spring bolts, however, often incorporate materials that offer improved corrosion resistance, such as stainless steel or coated alloys, thus extending their lifespan even under harsh environmental conditions. This aspect, along with their resistance to vibrations and loosening, positions folding spring bolts as a superior choice for applications requiring long-term reliability and minimal maintenance.

5. Assembly and Installation

Proper installation of folding spring bolts is essential to ensure the robustness, safety, and longevity of the connection, especially when used with clevises in various applications.

Installation steps:

- First, check the clevis and the bolt for any manufacturer guidelines, including recommended material compatibility.

- Align the holes of the cross bore of the clevis into which the folding spring bolt will be inserted. If dealing with custom designs or specific industrial applications, refer to any available diagrams to ensure proper alignment.

- Insert the folding spring bolt through the aligned holes of the cross hole. The spring mechanism should ideally face in a direction that ensures easy access for future adjustments or maintenance.

- Ensure that the bolt is fully extended and the spring mechanism is engaged above the shaft of the clevis. This may require slight pressure or adjustment of the bolt to lock it in place.

- Once the bolt is securely fastened, carry out any necessary final adjustments. This could include tightening the clevis to the recommended torque.

Final checks: After installation, it is important to double-check the assembly. Ensure the bolt is properly inserted and there is no unacceptable movement at the connection point. Test the setup under safe, controlled conditions to verify the load-bearing capacity and safety of the fastening. Regular maintenance checks are recommended to identify wear or corrosion that could affect the integrity of the fastening over time.

6. Care and Maintenance

Maintaining folding spring bolts is crucial to ensure their reliability and performance over time. Given their mechanical nature and the environments they are used in, a tailored maintenance approach can significantly extend their lifespan.

Regular inspection:

Checking for Wear and Damage: Regularly inspect the folding spring bolt for signs of wear, damage, or corrosion. Pay particular attention to the condition of the spring and the bolt.

Functionality Test: Ensure that the folding spring bolt operates correctly. The bolt should retract and lock smoothly. Any sticking or difficulty in operation may indicate a problem.

Cleaning:

Removing Dirt and Debris: Regularly clean the folding spring bolt with a clean cloth. For heavy soiling, a mild detergent and water can be used. Ensure the bolt is completely dry before reuse.

Preventing corrosion: In high humidity environments or those with aggressive chemicals, the folding spring bolt may corrode. Use corrosion protection agents if necessary to protect the bolt.

Lubrication:

Application of lubricant: Apply a thin layer of appropriate lubricant (e.g., silicone spray, Teflon spray, or light machine oil) at regular intervals to maintain bolt mobility and minimize friction.

Selecting the Right Lubricant: Use a lubricant suitable for the specific application area of the folding spring bolt. Avoid lubricants that attract dust and dirt.

Replacing parts:

Replacement of damaged parts: If inspection reveals that parts of the folding spring bolt are damaged or worn, replace them as soon as possible. This includes the bolt, spring, and possibly other securing elements.

Storage:

Proper Storage: When the folding spring bolt is not in use for an extended period, store it in a dry and clean place. Avoid areas with extreme temperatures or high humidity to prevent corrosion and damage.

By implementing these maintenance and care strategies, the longevity and performance of folding spring bolts can be significantly improved, providing reliable fastening solutions for a wide range of applications.