Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

Angle joints similar to DIN 71802 form CS with sealing cap serve as mechanical guide and corner connection elements for power transmission in different directions. This form with sealing cap is specifically designed for problematic environmental conditions (dust, lubricants, dirt, splashing water, vapors, etc.). The space between the ball socket and ball stud is covered and sealed by a sealing cap. This provides the best protection against destruction by environmental influences. These caps are made from robust chloroprene and can be used in a wide temperature range from -30°C to +110°C. They can even withstand temperatures up to +140°C for short periods, underscoring their versatility and durability.

Angle joints are fundamentally available in all standard versions with sealing cap and are also available in steel or stainless steel, including the axial joints.

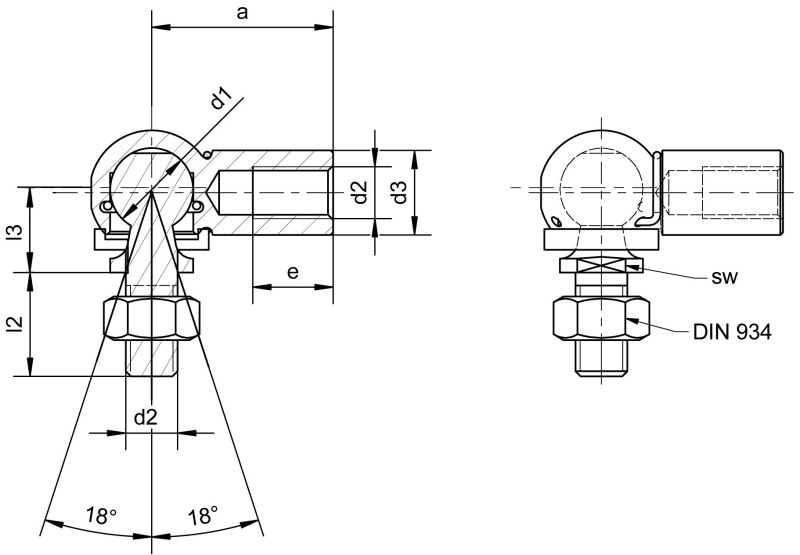

An angle joint is an assembly. The following list describes the individual parts of the form CS version with sealing cap, similar to DIN 71802:

- Ball socket DIN 71805

The ball socket accommodates the ball stud and allows unrestricted movements in any direction. Due to its precise manufacturing, it ensures low friction function and long-term stability. - Ball stud DIN 71803

The ball stud is inserted into the ball socket and provides the necessary movability of the joint. It features a male thread and a spanner surface for easy assembly. - Snap ring

This snap ring holds the ball stud in the ball socket and prevents unintentional release. - Circlip DIN 71805

The circlip is an additional securing element and fixes the ball stud in the ball socket to provide more safety. - Sealing cap

The sealing cap offers protection from dust, dirt, splashes, and vapors, it extends the lifespan of the joints and reduces maintenance efforts. - Hex nut DIN 934

A hex nut is supplied loosely for fastening and additional securing of the ball stud. - Lubricating grease

To reduce friction between the ball stud and the ball socket and to extend the life of the joint, lubricating grease is applied to the ball socket.

2. Product details

Size: CS 8 M5 - CS 19 M16

Material group: Steel, stainless steel, stainless steel A4 quality

Surface: bright, electr. galvanised white

Thread version: Regular thread right and left, fine-pitch thread right

d1 Ball diameter: 8 - 19

d2 Thread: M5 x 0,8 - M16 x 2

3. Application Areas & Compatibility

Angle joints with sealing cap are preferred in areas where force transmission is performed as a corner connection. A crucial advantage is that they are movable in all directions due to their component geometry, which can result in point force transmission in the application. In addition, angle joints are often also used for angle and play compensation. The use of sealing caps is particularly meaningful in environments and applications where protection against dust, dirt, splashes, and vapors is essential.

Typical application areas include:

Mechanical engineering: Angle joints with sealing cap find versatile applications in general mechanical engineering as flexible and secure connections in various machines. Whether in production plants, conveyor technology, or robotics—wherever precise movements and flexible force transmissions are required, they are used. Their ability to transmit movements in different directions makes them an essential component for complex mechanisms and contributes to high efficiency and durability of machines. The advantage of the sealing cap lies in the protection of the joints in machines and systems that are used in dusty or dirty production environments.

Agricultural and construction machinery: In agricultural and construction machinery, angle joints with sealing caps are used as movable linking elements in various machines and devices. They serve as joint connections in tractors, combines, and other agricultural machinery that operate under extremely dusty and often muddy conditions. Moreover, they are used in the joints of excavators, wheel loaders, and other construction machinery that are operated in dirty, moist, and abrasive environments. Particularly through the sealing cap, these angle joints ensure reliable force transmission and mobility required to perform various work processes efficiently and safely.

Railway industry: In the railway industry, angle joints with sealing cap are used in connections and axle journals. Especially in the complex chassis constructions of trains, they are indispensable, as they ensure a flexible yet stable connection between the various moving parts of the chassis systems. This ensures the stability and safety of the vehicles, even under extreme loads and varying movements. The advantage of the sealing cap here also lies in the protection against dirty, moist, and abrasive environments.

Fitness and rehabilitation technology: Angle joints with sealing cap are used in movable components of fitness equipment and rehabilitation technology, like wheelchairs or walking aids. Here, they ensure the necessary precision and flexibility to enable complex movements and adjustments. The sealing cap increases protection against contamination and corrosion, extends the service life, and reduces maintenance effort, thereby improving the hygiene and reliability of rehabilitation and fitness equipment.

4. Advantages and Benefits

Angle joints with sealing cap are protected from dust, dirt, moisture, or other abrasive environmental conditions. This feature reduces wear and maintenance effort, improves operational safety, and increases longevity. Thus, these angle joints contribute to a reduction in overall costs.

Of course, all other general advantages of angle joints DIN 71802 form CS also apply to the angle joints with sealing cap.

5. Assembly and Installation

Assembly

The assembly of an angle joint similar to DIN 71802 form CS with sealing cap is carried out in the following steps:

- Insert lubricant into the ball socket's cup

- Press the snap ring into the groove of the ball socket so that it can move freely within it

- Push the ball stud through the sealing cap, ball first

- Push the ball stud through the snap ring and downward into the ball socket until it snaps into place

- Install the circlip

- Optional: Screw the hexagon nut onto the thread of the ball stud (according to DIN 71802, the nut is included loosely)

Installation

Angle joints with sealing cap are typically firmly connected to the adjacent components. The simplest way to connect them is through the female thread of the ball socket or the male thread of the ball stud with matching counterparts. It is essential to pay attention solely to a certain dimensional tolerance of the respective counterpart.

6. Safety instructions & Standards

Safety instructions

Observe load limits: Ensure not to exceed the specified load limits of angle joints with sealing cap to avoid mechanical failure and possible injuries.

Regular inspection: Conduct regular maintenance and inspections of the angle joints and sealing cap to ensure they are in perfect condition and do not show signs of wear or damage.

Correct installation: Make sure the angle joints with sealing cap are properly and securely installed, as incorrect installation can cause failures and safety risks.

Check material compatibility: Before installation, ensure that the sealing cap made of chloroprene is compatible with the lubricants and operating materials used.

Avoid overuse: Avoid abrupt or extreme movements as they might overstrain the angle joints with sealing cap.

Use of suitable fasteners: Only use appropriate and specified screws and nuts for securing the angle joints with sealing cap, as improper fasteners can impair function and safety.

Standards and norms for angle joints similar to DIN 71802 with sealing cap

DIN 71802: This standard sets the requirements for angle joints, including their dimensions, mechanical properties, and material requirements.

DIN 71805: This standard defines the dimensions, materials, and mechanical properties for ball sockets regarding their requirements.

DIN 71803: This norm specifies all crucial dimensions and technical details for ball studs. Ball studs DIN 71803 are the matching counterpart to ball sockets according to DIN 71805. When assembled, they form an angle joint according to DIN 71802.

DIN ISO 1629: This standard includes designations and definitions of elastomers, including chloroprene, from which sealing caps are typically made.

Material standards: The materials used should conform to the relevant material standards, such as DIN EN 10088 (stainless steels), to ensure they exhibit the required mechanical properties and corrosion resistance.

Adhering to safety instructions and standards is essential for the safe function and longevity of angle joints similar to DIN 71802 Form CS with sealing cap. Regular inspections, correct installation, the use of suitable materials, and staff training are necessary to prevent accidents and failures. Complying with DIN, ISO, and material standards ensures that the angle joints meet high quality and safety standards.